Supplying Stainless Steel Pipes, Plates, Rod, Flat, Pipe Fittings & etc. in all Grade & Size. We are Manufacturer, Trader and Supplier

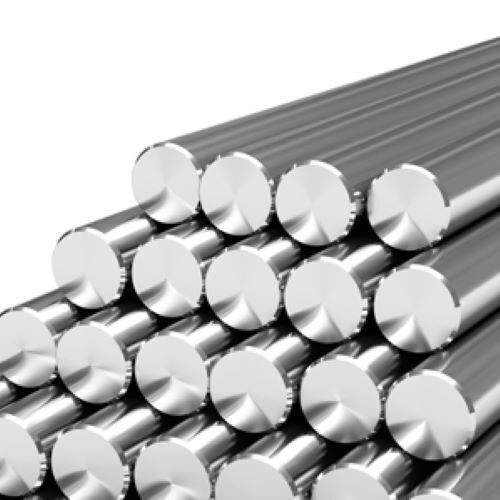

Inconel Round Bars

Price 2000 INR/ Kilograms

MOQ : 10 Kilograms

Inconel Round Bars Specification

- Heat Resistance

- Yes

- Diameter

- 6mm to 300mm or as specified

- Hardness

- 170â350 HB (Brinell Hardness, varies with grade)

- Material Composition %

- Nickel (72% min), Chromium (14â17%), Iron (6â10%)âvaries by grade

- Coating Type

- Uncoated or as per requirement

- Tensile Strength

- 690â1240 MPa (varies by grade)

- Recyclable

- Yes

- Product Form

- Solid Bar

- Size

- Custom sizes available

- Corrosion Resistant

- Yes, excellent resistance to oxidation and corrosion

- Product Name

- Inconel Round Bars

- Steel Type

- Nickel-based Super Alloy

- Steel Product Type

- Round Bar

- Grade

- Inconel 600, 601, 625, 718, 800, 825 (as ordered)

- Thickness

- Varies with diameter (customizable)

- Shape

- Round

- Steel Standard

- ASTM B166 / ASME SB166 / DIN 17752 / EN 10204

- Surface

- Bright, Polished, Peeled, Black, Turned

- Composition

- Nickel, Chromium, Iron, Molybdenum (varies by grade)

- Application

- Chemical processing, Aerospace, Marine, Power generation, Oil & gas industries

- Dimension (L*W*H)

- As per requirement (customizable lengths and diameters)

- Weight

- Depends on diameter and length; specified on order

- Color

- Metallic silver-grey

- Material Grade

- Inconel 600, 601, 625, 718, etc.

- Finish Type

- Polished, Peeled, Turned, Bright

- Usage

- High temperature and corrosive environments

- Delivery Condition

- Annealed, Cold-drawn or Hot-rolled

- Elongation

- 30–40% (varies by grade)

- Melting Point

- 1320–1380 °C (varies by grade)

- Magnetic Properties

- Non-magnetic in annealed condition

- Impact Strength

- High ductility, excellent toughness

- Machinability

- Moderate to difficult

- Packaging Type

- Wooden cases, Bundles, as required

Inconel Round Bars Trade Information

- Minimum Order Quantity

- 10 Kilograms

- Supply Ability

- 10000 Kilograms Per Month

- Delivery Time

- 1-2 Days

About Inconel Round Bars

Highlighted as an elite choice, our Inconel Round Bars are ending soon at an outstanding sale price! Perfect for demanding environments, these monumental nickel-based super alloys offer a melting point of 1320-1380 C and elongation of 30-40%. Supplied in custom dimensions and grades (Inconel 600, 601, 625, 718, 800, 825), each bar boasts high ductility, excellent toughness, and exceptional corrosion resistance. With a non-magnetic annealed condition, moderate machinability, and superior heat resistance, these bars deliver peak performance for aerospace, chemical, marine, and power generation sectors. Secure your order today!

Versatile Applications & Enhanced Features

Inconel Round Bars stand out for their wide application range, including exhaust systems, turbine components, and high-temperature reactors, apart from chemical and marine industries. Extra features include customizable diameters, solid construction, and resistance to aggressive chemicals. Used for both heavy-duty engineering and precision projects, their recyclable nature and bright, polished surfaces make them a preferred choice for elite manufacturers and traders across India.

Timely Delivery and Export Excellence

We prioritize prompt dispatching of Inconel Round Bars from major FOB ports in India, ensuring quick delivery to global destinations and domestic markets. Our streamlined logistics cater to manufacturers, wholesalers, and distributors, providing competitive sale prices. The bars are securely packed in wooden cases or bundles, as per customer requirements, maximizing export quality and minimizing transit risks for international buyers.

Versatile Applications & Enhanced Features

Inconel Round Bars stand out for their wide application range, including exhaust systems, turbine components, and high-temperature reactors, apart from chemical and marine industries. Extra features include customizable diameters, solid construction, and resistance to aggressive chemicals. Used for both heavy-duty engineering and precision projects, their recyclable nature and bright, polished surfaces make them a preferred choice for elite manufacturers and traders across India.

Timely Delivery and Export Excellence

We prioritize prompt dispatching of Inconel Round Bars from major FOB ports in India, ensuring quick delivery to global destinations and domestic markets. Our streamlined logistics cater to manufacturers, wholesalers, and distributors, providing competitive sale prices. The bars are securely packed in wooden cases or bundles, as per customer requirements, maximizing export quality and minimizing transit risks for international buyers.

FAQ's of Inconel Round Bars:

Q: How are Inconel Round Bars typically packaged for shipment?

A: Inconel Round Bars are packaged in sturdy wooden cases or bundled securely, as directed by the customer's requirements, ensuring protection during transportation to domestic or export markets.Q: What grades of Inconel Round Bars are available for order?

A: Available grades include Inconel 600, 601, 625, 718, 800, and 825. Selection can be tailored based on the specific application and desired material properties.Q: Where can Inconel Round Bars be used most effectively?

A: They are most effective in environments requiring high corrosion and heat resistance, such as aerospace, marine, chemical processing, oil & gas, and power generation sectors.Q: What is the delivery process for Inconel Round Bars in India?

A: Upon order, bars are promptly dispatched from major ports after precise packing. Delivery timing and logistics are coordinated to meet the needs of both domestic and global buyers.Q: What benefits do Inconel Round Bars offer for industrial applications?

A: They deliver exceptional toughness, high ductility, and resistance to oxidation and corrosion, maintaining integrity even at extreme temperatures, making them indispensable for heavy-duty and precision engineering.Q: Can the dimensions and diameter of Inconel Round Bars be customized?

A: Yes, both length and diameter can be customized to specification, accommodating project-specific requirements for size and weight.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Inconel Products Category

INCONEL PIPE FITTINGS

Price 2600 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Warranty : 1 Year

Color : Sliver

Usage : Industrial

Surface : Polished

INCONEL HEX NUT BOLTS

Price 400 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Warranty : 1 Year

Color : Sliver

Usage : Industrial

Surface : Polished

INCONEL FLANGES

Price 2800 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Warranty : 1 Year

Color : Sliver

Usage : Industrial

Surface : Polished

INCONEL BUTT WELD FITTINGS

Price 1800 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Warranty : 1 Year

Color : Sliver

Usage : Industrial

Surface : Polished

Send Email

Send Email  Send Inquiry

Send Inquiry